PEMSERTER® NextGen

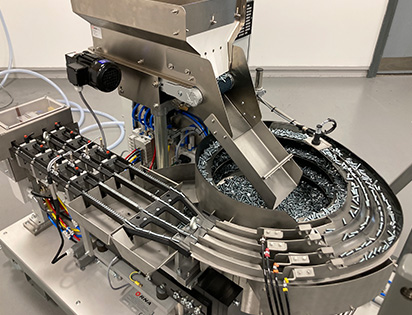

Universal In-Die Feed Cart

This modular, plug-and-play system is designed for efficient and accurate installation of PEM® self clinching fasteners during the stamping process. This system streamlines operations by eliminating secondary processes, reducing costs, and improving quality and throughput. With quick-change tooling and compatibility with most fastener types, it supports flexible production and integration with Industry 4.0 systems. Ideal for transfer and progressive stamping, the NextGen solution enhances productivity while minimizing capital investment.

| Specifications | |

|---|---|

| Footprint (LxWxH) | 1.5m x 1m x 2m |

| Weight | 745kg |

| Electrical Requirements | 230V single phase supply |

| Air Requirements | 6 / 7 bar ID Ø12mm MIM |

| Press Speeds | up to 65 strokes per minute |

| Control System | Siemens ET200-1510 |

| Operator Interface | Siemens HMI touch screen |

| Hopper Capacity | 25 litre |

| Number of Feed Lines | 4x (other configurations by review) |

| Manoeuvrability | Easy roll/swivel wheels |

| Supplied configured to suit a PEM® nut type | STM/SSTM M5 thru M8 |

| Supplied configured to suit a PEM® stud type | FHTM/HFHTM/HFETM/THFETM M5-12 thru M8-35 |

| PEM® fastener size Interchangeability | Yes |

| PEM® fastener type Interchangeability | Yes |

| Multiple bowls per cart | Yes – custom solution |

PEMSERTER MODULAR DESIGN

Modular design enables rapid and repeatable changeover, offering unique flexibility. The system can be configured to feed many PEM fastener styles, limiting the need to invest in multiple feed systems.

PLUG-AND-PLAY

The system interfaces with the die and press with ease. Through use of quick connectors, it is virtually plug-and-play. All that is needed to operate the cart is a single-phase power supply and shop air.