Introducing the Haeger T-Series

Tailored for Server Cabinet Manufacturing

Available in three optimized models, the T-Series adapts perfectly to different production needs:

– T600: Designed for compact, box-like components such as 19” rack internals. With an extended Z-axis stroke, it handles flanges up to 140 mm high for nut insertion or 120 mm for studs — even when the flanges are upright.

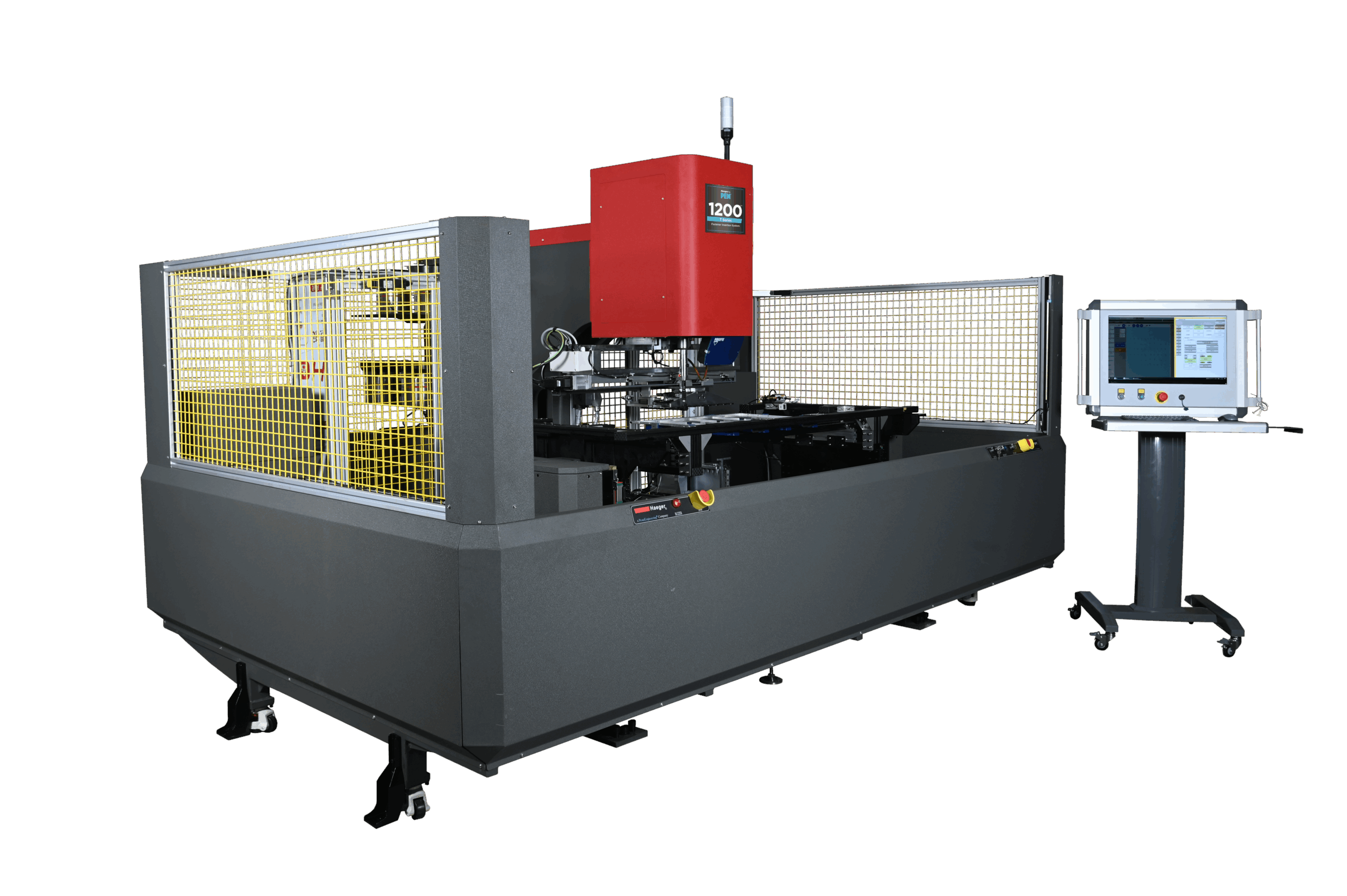

– T1200: The flexible all-rounder. Ideal for a wide variety of parts and mixed production environments, offering a perfect balance between working range and footprint.

– T2400: Built for large, flat components like cabinet side panels. It supports part lengths up to 2400 mm, with flange height capabilities of up to 50–70 mm — optimized for wide but

shallow parts.

No More Manual Errors

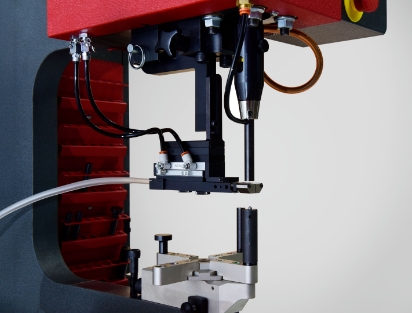

With complex parts and high fastener counts, manual insertion is slow and error-prone. The T-Series eliminates operator mistakes by automating the entire process. An integrated 3D camera

ensures precise part alignment and inspects every fastener after installation — for position, height, and diameter. That means fewer defects, reduced scrap, and consistent quality, even across high-volume runs.

Fast. Flexible. Fully Automated.

The T-Series features a high-speed XYZ table that positions each insertion point with pinpoint accuracy. Once the part

is loaded, the system takes care of tool selection, fastener feeding, installation, and quality inspection.

Up to 8 vibratory bowl feeders can be configured per system, allowing seamless transitions between different

fastener types. Automatic tool changers (top and bottom) further eliminate the need for manual intervention, even

during mixed part runs.

Engineered for Speed and Reliability

At its core, the T-Series runs on Haeger’s servo-driven press system — the same technology behind the 824E-Drive. This ensures high-speed cycles, accurate

force and stroke control, and a fastener insertion time of just 3–5 seconds (excluding table movement).

Whether your focus is speed, repeatability, or process control — the T-Series delivers.

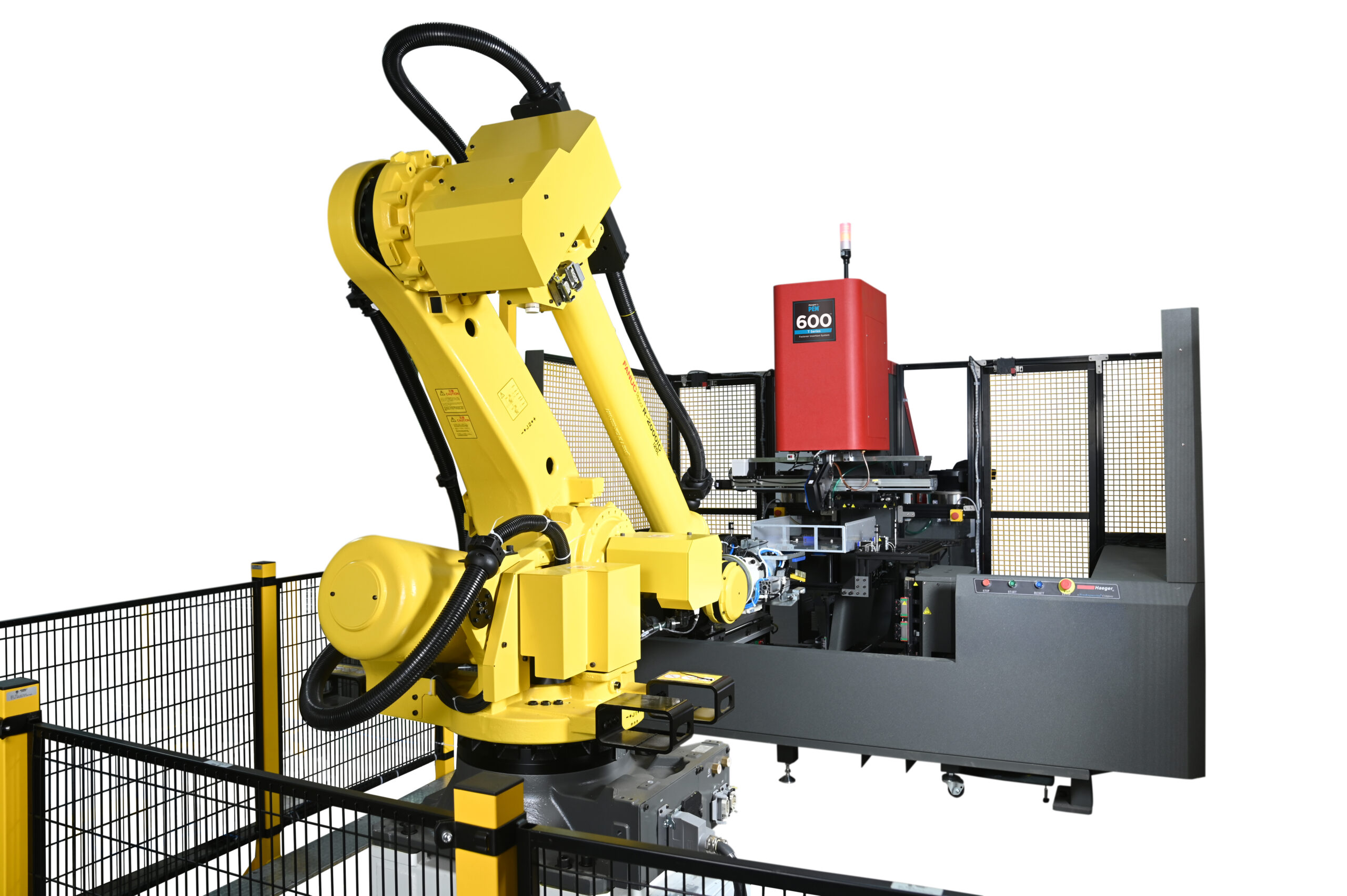

Smart Connectivity and Integration

Built for Industry 4.0, the T-Series is ready to integrate with MES systems, robot cells, and full-scale production lines. Its PMCS control system supports standard communication protocols for easy data

exchange and remote monitoring. In a fully automated setup, a robot gantry can load parts directly from pallets, completely removing human involvement from the process. Programming is quick and intuitive via CAD import and recipe

management — ideal for high-mix, fast-paced production.

Certified and Ready for Global Use with Automation

All T-Series models are CE certified and meet international safety standards, ensuring compliance across global operations.

Whether you’re producing thousands of identical parts or managing a wide range of component types, the Haeger T-Series gives you a competitive edge. Reduce labor dependency, eliminate errors, and

boost production efficiency — with the most intelligent fastener installation system we’ve ever built.

| Specifications | |||

|---|---|---|---|

| PAT600-E | PAT1200-E | PAT2400-E | |

| Control System Type | Electric actuator, Motion Control, 3D Camera system, PMCS controls system | ||

| Force Range | 8 to 80KN | 8 to 80KN | 8 to 80KN |

| Repeatability | ±1kN (10kN – 60kN) ±1% of force setting / ±0.02mm of position setting | ||

| Stroke Length | 0-300mm | 0-200mm | 0-200mm |

| Speed | Ram down/retract max. 200mm/s | ||

| Auto Feed / Toolchange | 4 station topfeed | up to 8 station topfeed | up to 8 station topfeed |

| Feeder Bowl | MAS350 | MAS350 | MAS350 |

| Panel Processing Range | 600mm x 600mm | 1200mm x 800mm | 0mm x 800mm |

| Panel Flange Height | Nut 140mm, Stud | Nut 70mm, Stud 50mm | Nut 70mm, Stud 50mm |

| Clinching Capability | 1mm to 6mm combined thickness | ||

| Panel Weight | 40Kg Max | 40Kg Max | 40Kg Max |

| Fastener Range | M2.5-M8 | M2.5-M8 | M2.5-M8 |

| Air Requirement | 6-7 Bar | 6-7 Bar | 6-7 Bar |

| Electric Requirement | 380-400V 3phase 50 or 60Hz | ||

| Power | 13kW | 13.5kW | 13.5kW |

| Dimensions (Dxwxh) | 2700mmx3000mmx2600mm | 3000mmx3800mmx2490mm | 3100mmx6600mmx2490mm |

| Weight | 4300Kg | 4500Kg | 6200Kg |