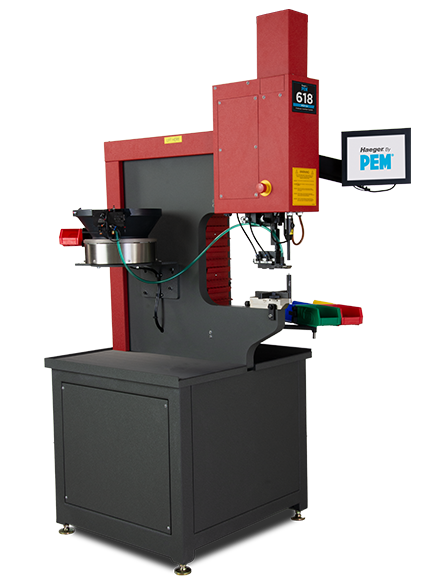

618™ MSP 5e

The 618 MSP 5e features 6 tons (53 kN) of ram force, a throat depth of 18″ (450 mm) plus an adjustable ram retract position. You can also count on the reliability and energy efficiency of a fully hydraulic machine that also offers our patented safety system, tooling protection system, and batch counter.

| Specifications | |

|---|---|

| Fastener Range | #2-56 to 1/2″ (M8 stud, M12 nut) |

| Force Range | Adjustable 600 lbs to 12,000 lbs (2.6-53 kN) |

| Drive System Type | Hydraulic |

| Insertions per Hour | Up to 1,400 |

| Control System | Insertion Logic |

| Auto-Feed | Optional |

| Batch Counter | Standard |

| Fastener Database | Standard |

| Insertion Graphics | No |

| Fastener Length Detection | No |

| Positive Stop | N/A |

| Screen Size | 10″ |

| Robot Ready | Optional |

| Remote Connection | Standard |

| Repeatability | +/- 2% of force setting |

| Throat Depth | 18″ (450 mm) |

| Stroke Length | 0 to 8.0″ (0 to 200 mm) |

| Up Travel % | 10-100% |

| Electrical Requirements | 3 Phase Low 9 A 208-240 V or High 3.7 A 380-480 V |

| Air Requirements | 90 to 100 PSI (6 to 7 BAR) 1/2″ (12mm) dia. minimum line flow |

| Oil Reservoir Capacity | 10 gallons (39 liters) |

| Weight | 1,600 lbs (726 kg) |

| Footprint | 45″L x 34″W x 84″H (1092 mm x 864 mm x 2134 mm) |

IMPROVE EFFICENCY WITH MAS-350

Haeger standard MAS-350 auto-feed system supports the range of PEM standard hardware with a simple swap of modules between hardware types.

MULTI-SHUTTLE TOOLING PLATFORM

The Multi-Shuttle Platform provides universal quick and easy tool changeover between nuts, studs and standoffs—enabling two-minute total tool changes without realignment.